Henan Sinofiltec Technology Co.,Ltd

Ptfe Membrane,Separation Filter Elements,Coalescence Filter Elements,Coalescence Filter

Henan Sinofiltec Technology Co.,Ltd

Ptfe Membrane,Separation Filter Elements,Coalescence Filter Elements,Coalescence Filter

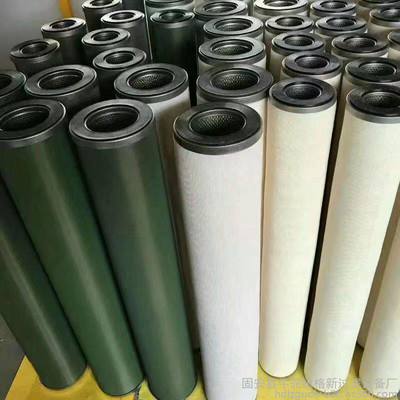

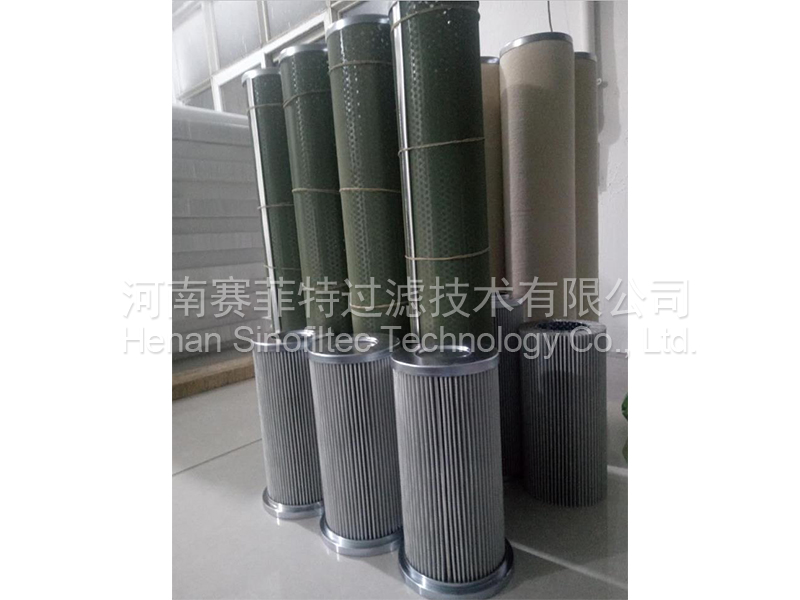

Coalescence &separation Filter Elements

Describe:

The coalescence separation filter element is generally cylindrical in shape, and the coalescence separation filter element is used in the oil-water separation system, mainly separating the oil-water mixture, suspension solution, emulsion solution, etc. The application flow of coalescence separation filter in the system can be divided into solid-liquid separation-demulsification-coalescence-separation. In the system, the number of Coalescence Filter and separation filter is better than that of 3:1, the effect of coalescence is good and the separation speed is fast.

Principle and characteristics:

The surface treated glass fiber or polyester fiber is mainly used as the coalescence medium. The structure of the Filter Material is 0.1 μ m by special design. The Filter Medium has good coalescence performance. Working process: after the emulsified oil enters the coalescence separator, it first enters the inner filter core from inside to outside, and the small liquid droplet in the dispersed phase changes from small to large. Finally, it falls off on the surface of the coalescence filter core and completes the coalescence process. In the process of flow separation, the larger water drops sink into the sink by gravity, and the small water droplets flow along with the oil to separate the filter elements. The separation filter has hydrophilic effect to block the passage of water. Small water beads collide to form large water droplets, which then settle into the sink again, thus dehydrating the oil.

Different packing sizes should be selected according to different oil-water systems: the smaller the packing size, the larger the specific surface area per unit mass and the larger the contact area with droplets. As a result, the performance of the coalescence filter element is enhanced. Therefore, it is suggested that the separation efficiency of coalescence filter should be taken into account when choosing fiber size, and the pressure drop should be taken into account at the same time.

Range of applications

1. Aviation fuel, gasoline, kerosene, diesel.

2. Cyclohexane, isopropanol, cycloacetone, etc.

3. Turbine oil and other low viscosity hydraulic oil, lubricating oil.

4. Other hydrocarbon compounds.

5. Liquefied petroleum gas, stone tar, benzene, toluene, xylene, cumene, polypropylbenzene and so on.