Henan Sinofiltec Technology Co.,Ltd

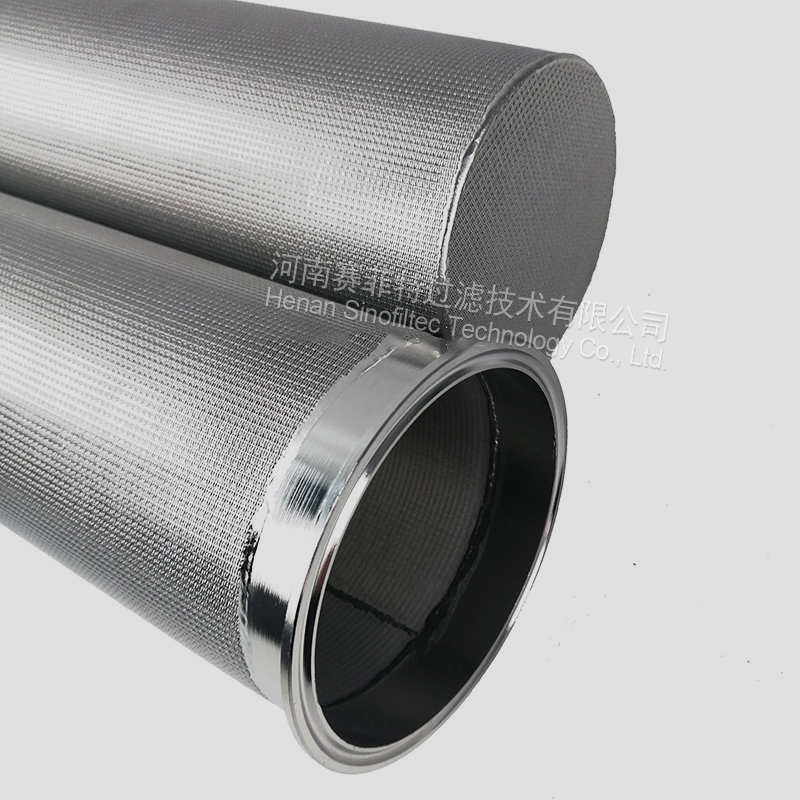

5-layer Sintered Mesh Filters,Sintered Wire Wesh 5-Layer Filters,SS316L Ssintered 5-layer Mesh Filter

Henan Sinofiltec Technology Co.,Ltd

5-layer Sintered Mesh Filters,Sintered Wire Wesh 5-Layer Filters,SS316L Ssintered 5-layer Mesh Filter

Model No.: FST-SFC-1/2/3/5 (1~400 microns)

Brand: SINOFILTEC

Material: Metal

Packaging: Plywood box or standard export packing

Productivity: 100,000 PCS/YEAR

Transportation: Ocean,Land,Air

Place of Origin: XINXIANG, CHINA

Supply Ability: 100,000PCS/YEAR

Certificate: ISO9001

HS Code: 8421999090

Port: SHANGHAI,QINGDAO,ZHENGZHOU

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

FST-SFC-1/2/3/5 (1~400 microns) Series Sintered Stainless steel 5-layer Wire mesh Filter:

Chacteristics and advantages:

This filter element has strong corrosion resistance, good permeability, high strength, easy to clean and reverse cleaning, accurate filtering precision, clean Filter Material, not falling off the screen.

1. Better strength, high mechanical strength and high crushing strength.

2. Stable air permeability and flow rate.

3.Can be used in -200℃~600℃ temperature environment and acid & alkaline environment of filtering.

4. Easy to backwash, long service life and can be used for many times.( can be cleaned against water, filtrate, ultrasonic wave, melted, baking etc cleaning methods).

Production describle:

The filter material of five-layer sintered mesh adopts standard five-layer sinter net. Standard five-layer sintering is five-layer stainless steel wire through superposition, vacuum sintering. With plasma or electron beam welding technology, SINOFILTEC company specializes in the production of sintered mesh filter elements. The filter mesh holes in each layer of wire mesh intersect with each other, thus forming a uniform and ideal filter structure. The material has advantages that ordinary wire mesh can not match, such as high strength, good rigidity, stable mesh shape, and so on.

Mainly Applciations:

1. Used as dispersing cooling material in high temperature environment.

2. Gas distribution, liquid bed orifice material.

3. High precision, high reliability high temperature filtration material.

4. High pressure backwash Oil Filter.

Specific industry application

1. Precision filtration of all kinds of hydraulic oil lubricating oil in machinery industry.

2. Filtration and purification of various polymer melts in chemical fiber film industry, filtration of various high temperature and corrosion solution in petrochemical industry, filtration of materials in pharmaceutical industry, washing and drying.

3. The application of gas homogenization in powder industry, fluidized plate in iron and steel industry.

4. Can be as the sound splitter in explosion-proof electrical apparatus.

Filter Material: SS316L.

Production structure: only 5-layer sintered mesh filter cartridge or with the innner and outer supporting stainless steel punching plate.

Main connection mode: Standard interface (such as 222,220,226), fast interface connection, thread connection, flange connection, pull rod connection, special custom interface.

Filter microns: from 1~400 microns

Note: We can customize the filter cartridges according to the customer's special requirements.

Product Categories : Metal Filter Elements > Porous Metal Filter Elements