Henan Sinofiltec Technology Co.,Ltd

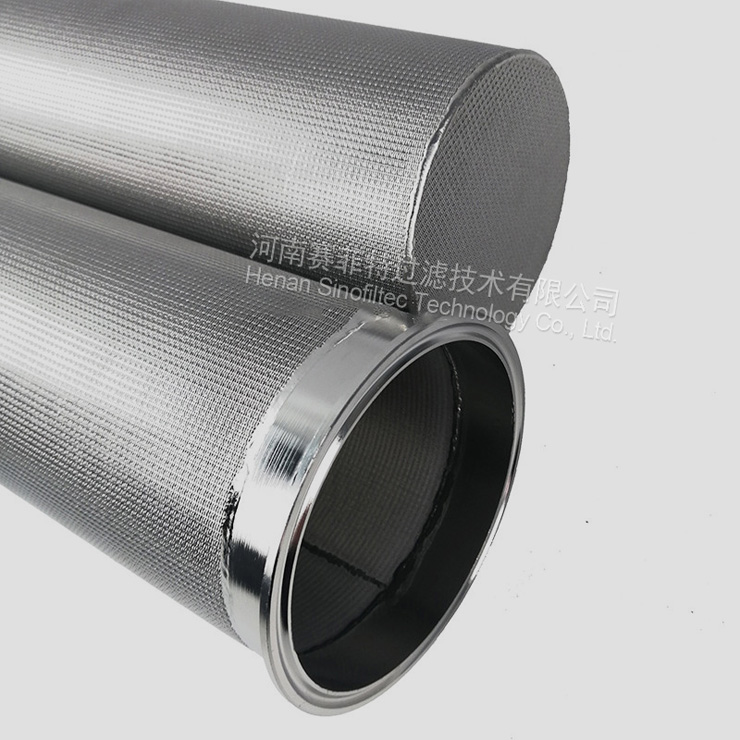

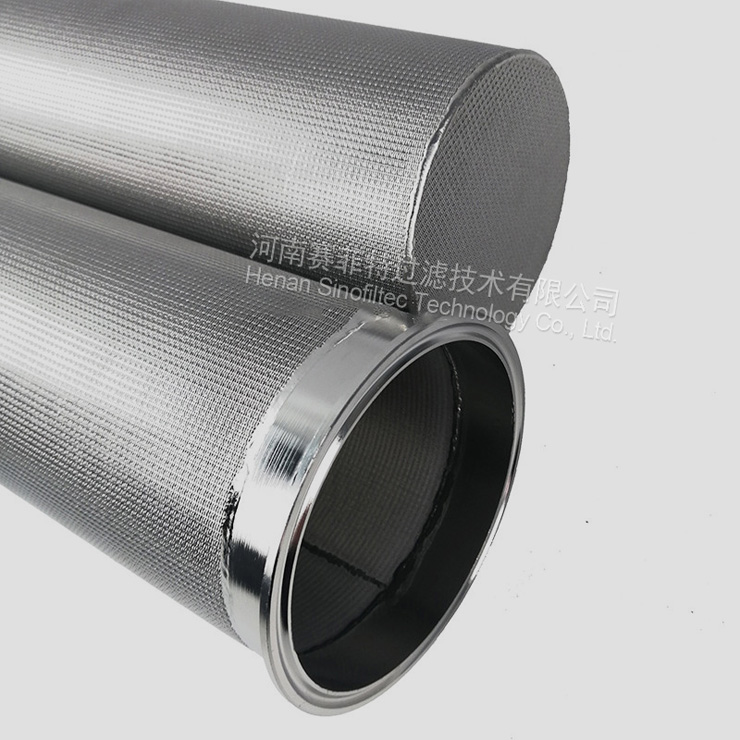

SS316L Sintered Wire Mesh Industrial Filters,Opposite Direction Rolling Filter Media Filter,SS316L 5 Layers Sintered Mesh Elements

Henan Sinofiltec Technology Co.,Ltd

SS316L Sintered Wire Mesh Industrial Filters,Opposite Direction Rolling Filter Media Filter,SS316L 5 Layers Sintered Mesh Elements

Model No.: FST-ORF-1/2/3/5/10/15/20/40/60/80/100/200/400

Brand: SINOFILTEC

Material: Metal

Type: Double Filter

Filter Connector: Flat Connector

Filtration Grade: Medium Filter

Packaging: Plywood box or standard export packing

Productivity: 50000 PCS/YEAR

Transportation: Ocean,Land,Air

Place of Origin: XINXIANG, CHINA

Supply Ability: 50000 PCS/YEAR

Certificate: ISO9001

HS Code: 8421999090

Port: QINGDAO,ZHENGZHOU,SHANGHAI

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

Production: Opposite Direction Rolling Sintered Wire Mesh Filter:

Production types: FST-ORF-1/2/3/5/10/15/20/40/60/80/100/200/400 microns with flanges.

Production describle:

Sintered mesh Stainless Steel Filter element is widely used in industrial application. It is a metal mesh Filter Material which is sintered by different mesh according to a certain formula and then rolled round and welded into filter element. Deconvolution of a circular filter core, the direction of fluid filtration is from the inside to the outside filtration. Filter element has high efficiency and long service life, combined with excellent cleaning and corrosion resistance, temperature resistance, it has good strength and chemical stability, filter element components are completely welded, Will not be subjected to the chemical filtration system caused by severe vibration cracks.

With extremely high mechanical strength and pressure resistance, machinability, welding and assembly, ideal for use in harsh environments. Sintered Metal Filters can be installed in our hydraulic filter, filter equipment, water filter combination, all of our wire stainless steel filter elements can be backflushed, Ultrasonic or other non-abrasive cleaning technology can be easily restored to use. When used for filtration applications involving dangerous liquids, the cleanability of our stainless steel filter elements can significantly reduce processing costs.

Technical Data:

| Filter material | Sintered 5-layers or multilayer wire mesh (316L) opposite direction rolling |

| Filter rating | 1~400microns (SS wire mesh) |

| DOE | Flat or flange ends |

| Length | 10".20".30".40" etc |

| Working temperature | -180℃~570℃ |

Note: We can produce other non-standard products according to customer's requirements.

Advantages:

(1)Low pressure drop:

The high porosity of our metal fiber media allows a very low pressure drop (and thus lower energy cost), even at high filtration velocities.

(2)Ease of cleaning:

The open structure of porous metal media allows you to clean in situ by backpulsing or backwashing.

(3)High strength:

The sintering process creates strong fiber bonds and guarantees a high strength Filter Medium. Combined with an appropriate inner core, our filter elements can withstand thermal shock, high pressures, and frequent backpulsing.

(4)Heat & corrosion resistance:

Our filter media can be used in high temperature (up to 1000° C, depending on the alloy) and/or corrosive applications - where non-metallic textile, ceramic or polymer products fail.

(5)Can be used for surface or depth filtration.

Our filter media enables you to achieve high efficiencies through a cake build-up (surface filtration) and also offer high dirt holding capacity for depth particles capture (depth filtration).

(6)Stainless steel and other alloys available:

Not brittle, chemical cleaning is possible, weldable, low thermal expansion, maintains structure (no thermal shock) Depending on the performance you require, we select the proper alloy to provide the required resistance and strength.

Applications:

(1)Polymer filtration: polyaramid, polyester, polypropylene, polyamide.

(2)Spinning polymer.

(3)Car: Air Filter, Oil Filter, air bag inflator filter.

(4)Chemical and catalyst recovery.

(5)High temperature liquid,Cryogenic liquid,Solvents, ketones, esters, liquid hydrocarbons,Water supply and lotion,Ethylene glycol.

(6)Efficient solids recovery or liquid recovery.

(7)Aerospace,Hot air filtration,Medical and pharmaceutical.

(8)Hydraulic and fuel,Nuclear ventilation.

(9)Food and drink:Process steam filtration,Catalyst is recovered from the hydrogenation reactor,Polished syrup, wine and other liquids.

Advantages:

(1) Extremely high porosity (up to 85%)

high flow rates: up to 20 times higher than other media types

long on-stream lifetime

downscaling is possible (less filter surface is needed to filter the same volume)

(2)Low pressure drop: The high porosity of our metal fiber media allows a very low pressure drop (and thus lower energy cost), even at high filtration velocities

(3)Ease of cleaning: The open structure of porous metal media allows you to clean in situ by backpulsing or backwashing

(4)High strength: The sintering process creates strong fiber bonds and guarantees a high strength filter medium. Combined with an appropriate inner core, our filter elements can withstand thermal shock, high pressures, and frequent backpulsing.

(5)Heat & corrosion resistance: Our filter media can be used in high temperature (up to 1000° C, depending on the alloy) and/or corrosive applications - where non-metallic textile, ceramic or polymer products fail

(6)Can be used for surface or depth filtration. Our filter media enables you to achieve high efficiencies through a cake build-up (surface filtration) and also offer high dirt holding capacity for depth particles capture (depth filtration)

(7)Stainless steel and other alloys available: Not brittle, chemical cleaning is possible, weldable, low thermal expansion, maintains structure (no thermal shock) Depending on the performance you require, we select the proper alloy to provide the required resistance and strength.

Product Categories : Metal Filter Elements > Porous Metal Filter Elements