Henan Sinofiltec Technology Co.,Ltd

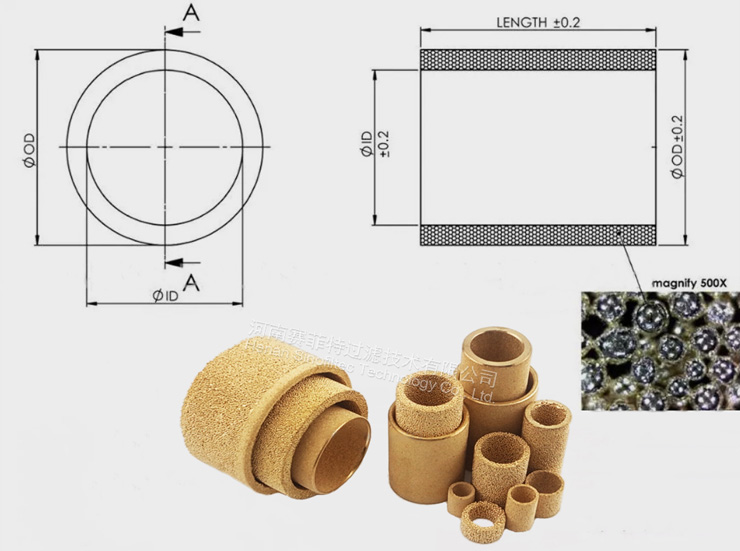

Bronze Powder Sintered Muffer,Sintered Bronze Powder Filter Tubes,Sintered Cooper Powder Elements

Henan Sinofiltec Technology Co.,Ltd

Bronze Powder Sintered Muffer,Sintered Bronze Powder Filter Tubes,Sintered Cooper Powder Elements

Model No.: FST-SBP-TB Series

Material: Metal

Type: Air Filter

Filter Connector: Flat Connector

Filtration Grade: PRE Filter

Activated Carbon Filter Type: Compact

Packaging: Plywood box or standard export packing

Transportation: Land,Air

Port: ZHENGZHOU,SHANGHAI,GUANGZHOU

Payment Type: T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

Sinofiltec bronze powder sintering element is first formed by static pressing, and then sintered by powder treatment at high temperature. Its internal pore bending configuration, crisscross, and uniform pore size distribution can be adjusted, and the pore size and distribution can be adjusted, and the pore size and distribution can be adjusted, and the pore size and distribution can be adjusted. The filtration mechanism is typical deep filtration. Based on many years of production experience, reliable production technology and process support, we can provide customers with drawing requirements and samples, select different filter materials (bronze powder, stainless steel, plastic, etc.) to produce the corresponding filter elements.

Characteristics and advantages:

The surface particles of sintered bronze filter element are not easy to fall off, the structure of the element itself is not easy to change, and it is resistant to impact and alternating load. It has excellent mechanical properties, can be machined such as cutting, welding and so on, and has high compressive strength. The maximum failure strength of internal pressure is more than 2mpa. The air temperature can reach-50 ℃ 500 ℃ the waste capacity is large and the regeneration method is simple and can be reused after regeneration. The cleanability of our sintered bronze Air Filter can significantly reduce the treatment cost. Suitable for filtration of all kinds of corrosive media, with extremely high porosity and long service life.

Main parameters:

| Filter Media | Bronze and stainless steel powder |

| Structure types | Tubular, conical, rounded and T-shaped |

| Sizes | Customizable for different sizes |

| Filter rating | 1~150 microns |

| Working Temperature | -20℃~250℃ |

Applications:

(1)Filtration of fluids. Porosity is able to retain the solid particles contained in a liquid or gaseous fluid, and also to separate liquid and solid phases. The application sectors are: automotive, marine, aeronautical, rail, industrial machinery, household appliances, heating, water depuration, food industry, chemical and nuclear industry, packaging manufacturing, tobacco pipes and electronic cigarettes, etc.

(2)Pressure drop. Porosity decreases the pressure of the fluid that circulates through it. Different applications are: pressure control in pneumatic and hydraulic circuits (compensators, drainers, regulators), noise absorption of gas piping (Silencers), pneumatic cylinders, sensors and manometers protection, gearboxes, etc.

(3)Flow control. The isotropic and homogeneous porosity allows that a fluid that circulates through it have a constant flow at the exit of the porous part. Typical applications are heat exchangers, medical gases, scuba diving, industrial gases, etc.

(4)Aeration. The air circulation through porosity results in a constant and controlled air flow at the exit of the porous component. The use sectors are: liquids repassing in food industry (liqueurs, wines, and gas beverages), ionization, gas burners, aquaria, clinical analysis, etc.

(5)Fluidization. The air circulation through the porous component has as result that the exit flow is distributed with the same pressure in all points, allowing then the controlled handling of powdered products. This property is used for: transporting cement, flour, alumina, ashes, toner powder, etc.

(6)Anti-moisture. Porosity is able to retain and condense the moisture contained in a gas that circles through it. Typical applications are: drying in general, electronic equipment`s protection, etc.

(7)Flame protection. Presence of a porous component before a flame avoids accidents in case of flame return. Typical applications are: gas burners, heaters, welding facilities, etc.

Product Categories : Metal Filter Elements > Porous Metal Filter Elements